On the bench:

February 5, 2026:

Headplates look better with they are bound. I learned early on when I was building furniture: Use contrast sparingly, define the boundaries of the piece, and frame interesting portions of the work. Binding the headplate uses minimal amounts of contrasting materials to create a well defined object. It says, “look here”, and “I’m neat and tidy”.

Bound is better.

Stiffness testing:

My approach to building guitars is fairly scientific (in the beginning).

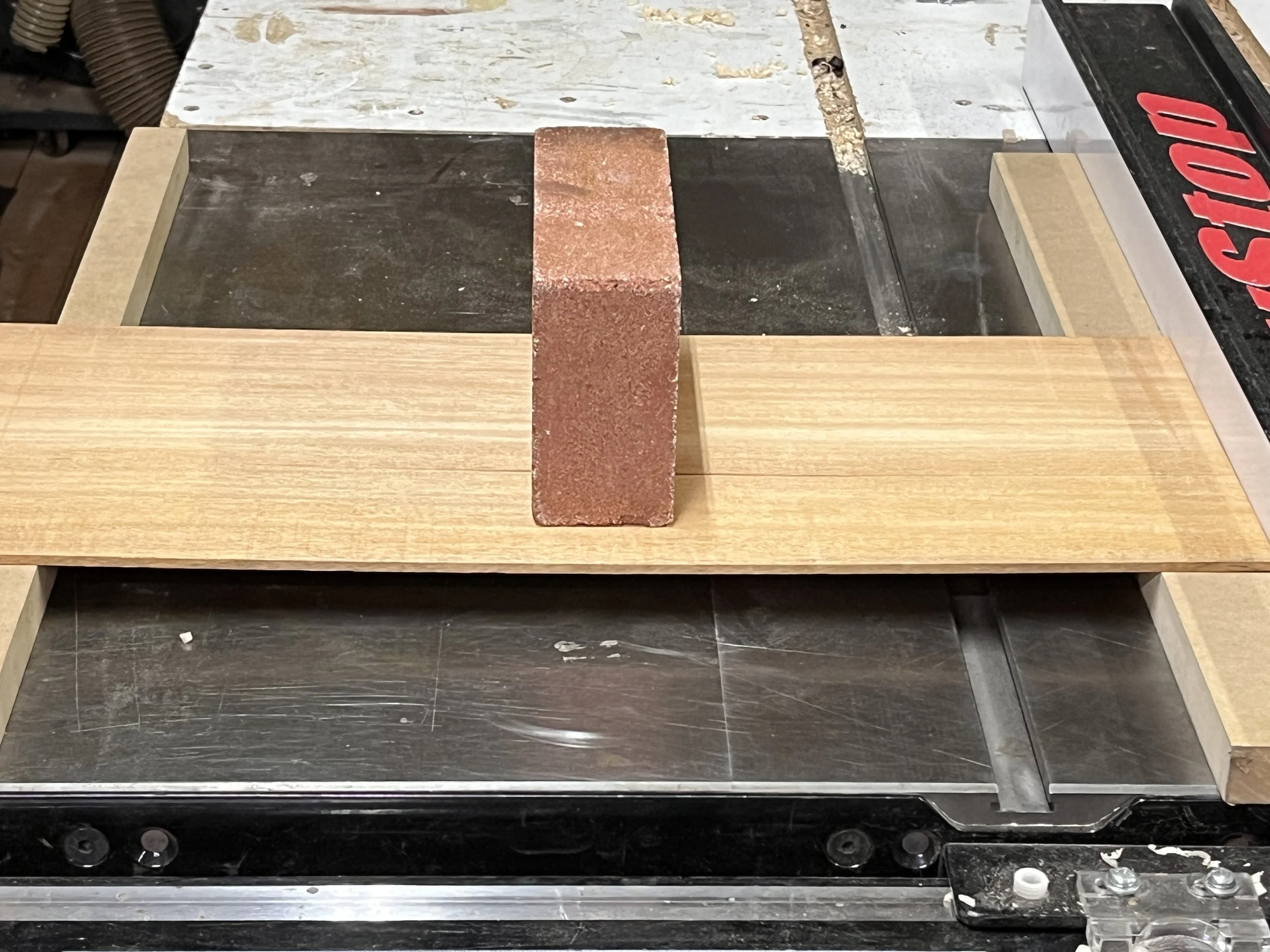

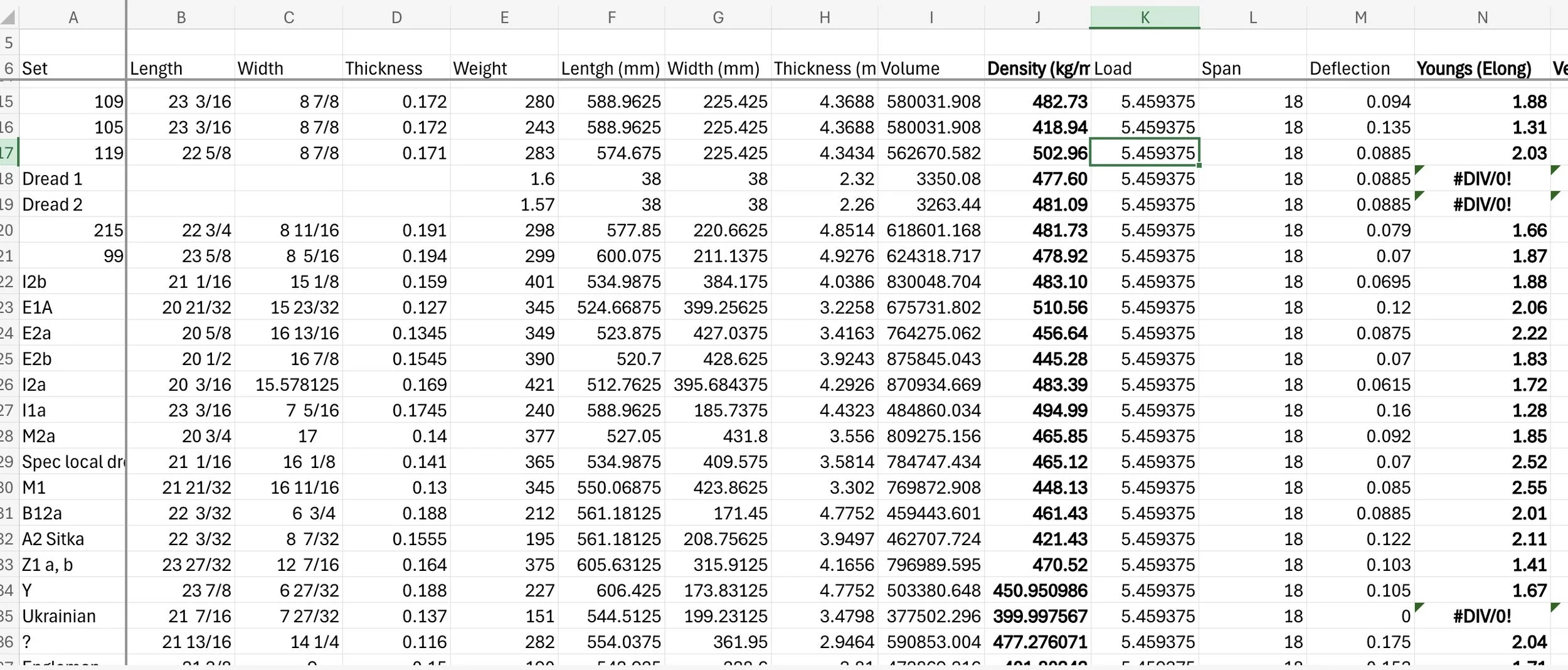

Before I start any guitar, I test the stiffness of each piece of wood used for backs and soundboards and do a bunch of calculations. First, each piece gets measured and weighed and I calculate the density. Then I measure the stiffness. The rig for stiffness testing is simple (brick on 18" span). Using this measurement, I calculate Young's Modulus of Elasticity. These measurements allow me to determine how thick (or thin) to make each soundboard (or back).

This is critical because you don't want extra weight in the soundboard, and you want it to be flexible enough to vibrate, and you want it stiff enough to resist the tension of the strings. This also gives me a consistent starting point for each guitar. When I have this information about the sounboard, I know how to brace it and the end result is fairly predictable. I record all this information.

These measurements also allow me to determine how heavy each soundboard will be, controlling for stiffness. This allows me to select a proper use for each soundboard. Fingerstyle guitars get the lighter ones because responsiveness is more important, flatpicking guitars usually get the heavier and stiffer ones because headroom and volume are more important.

This is a little math-y, but the interesting thing is that the stiffness of spruce tracks density very closely. So a less dense piece will be less stiff. But that doesn’t control for thickness, and we don’t care about stiff spruce, we care about stiff soundboards. It turns out that the stiffness of a beam is related to the cube of the Young’s Modulus of Elasticity. So if you double the thickness of a beam, it gets 8 times as stiff. What this means for guitars is that if we are comparing two potential soundboards, and we thickness the two candidates to the same stiffness (not the same thickness), the less dense on will be thicker but lighter. In general this is a good thing, so I often look for spruce that is less dense to get a lighter soudboard and a more responsive guitar.

Of course there is a little bit more to it than that...

High tech rig for stiffness testing (not shown, caliper for measuring the deflection).

Data informs experience, and vice versa.

January 31, 2026:

I closed the box on the mahogany guitar and have the neck and fingerboard roughed out. Should have finish on it early next week. Often the client will visit to handle the neck before the shaping is complete (one of the little benefits of a custom guitar).

January 28, 2026:

Second update for today…. I also have an all mahogany OM guitar underway. The soundboard for this guitar was an exceptionally light and resonant piece of mahogany. Usually hardwoods are heavy and don’t make great soundboards. This one was a different. I do some calculations regarding stiffness and density of the wood, and this soundboard will shakeout about as light as a heavy-ish piece of spruce, controlling for stiffness.

All mahogany guitars typically have a simpler look…IDK why. Anyway, that is the look we are going for on this one:

Rosette installed!

Here is a look under the hood before I glued the back on. Local clients get the opportunity to leave notes/messages/quotes/inspirational inscriptions on the interior of their guitar (blacked out).

January 28, 2026:

It has been a while! The Ganesha mini-jumbo is done and delivered. Another happy client!

The Super Jumbo has finish on it and is curing. Here are some of the pics from the build:

Curly maple binding will POP when the finish is on!

Neck roughed out

Headplate inlay

Fingerboard/neck/headplate, bound

Varnishing underway

Volute

Bound headplate

Soundboard

Partial assembly

Lastly, we are trying out a few pickguard shapes:

December 28, 2025:

I picked up 4 sets of very nice koa. Straight grained and super taptone, lush with great sustain.

Koa! I HOPE this will be on the bench soon.

December 28, 2025:

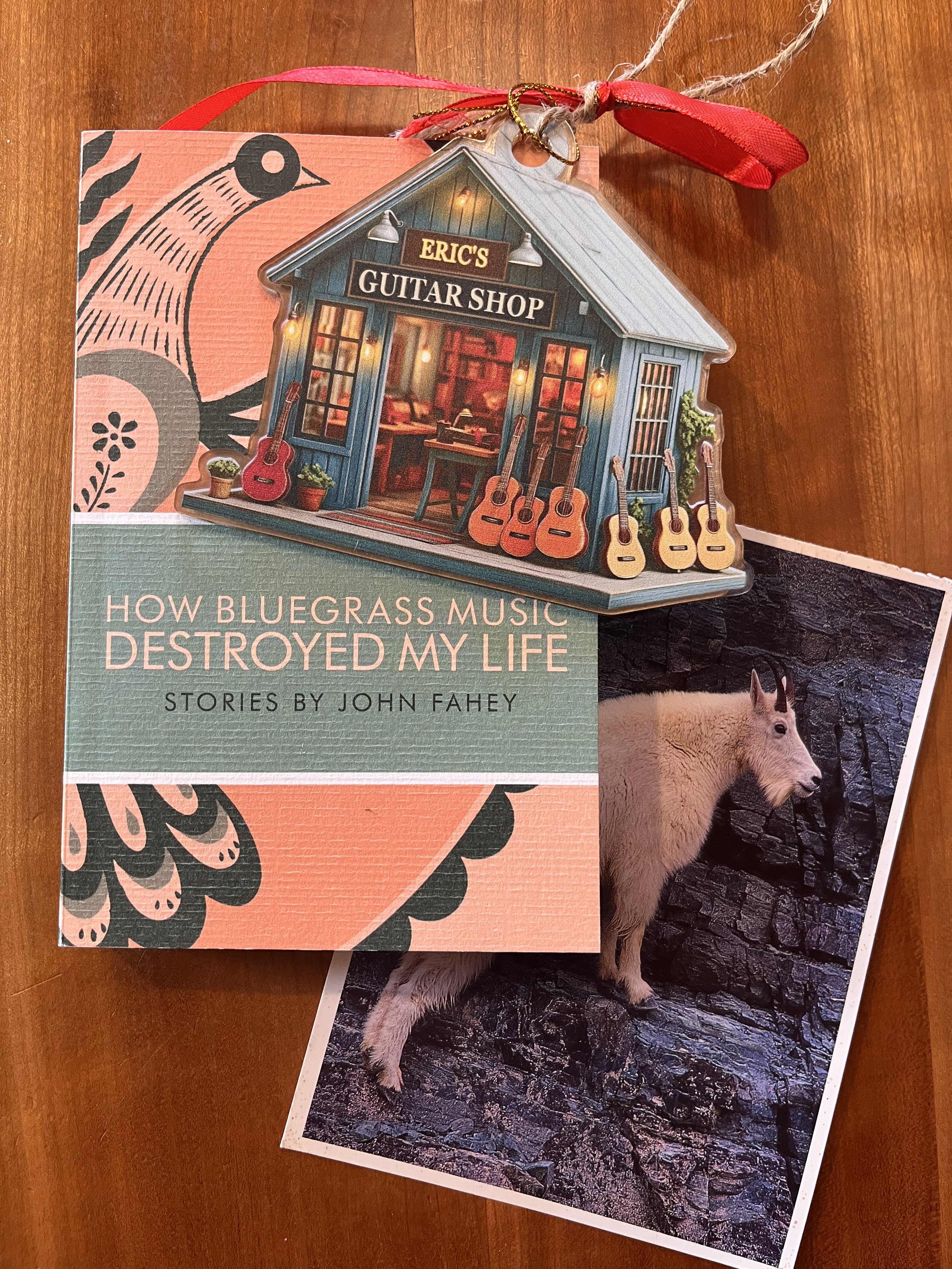

Some appreciations from my customers. Making instruments is a bit of a personal obsession. But instruments are very personal for some players, and its really satisfying to be able to build someone “their” guitar.

Pictures of the Ganesha guitar. Hopefully I will have some audio soon.

Gluing on the neck/fingerboard. I’ve gone back to the standard method, for simplicity.

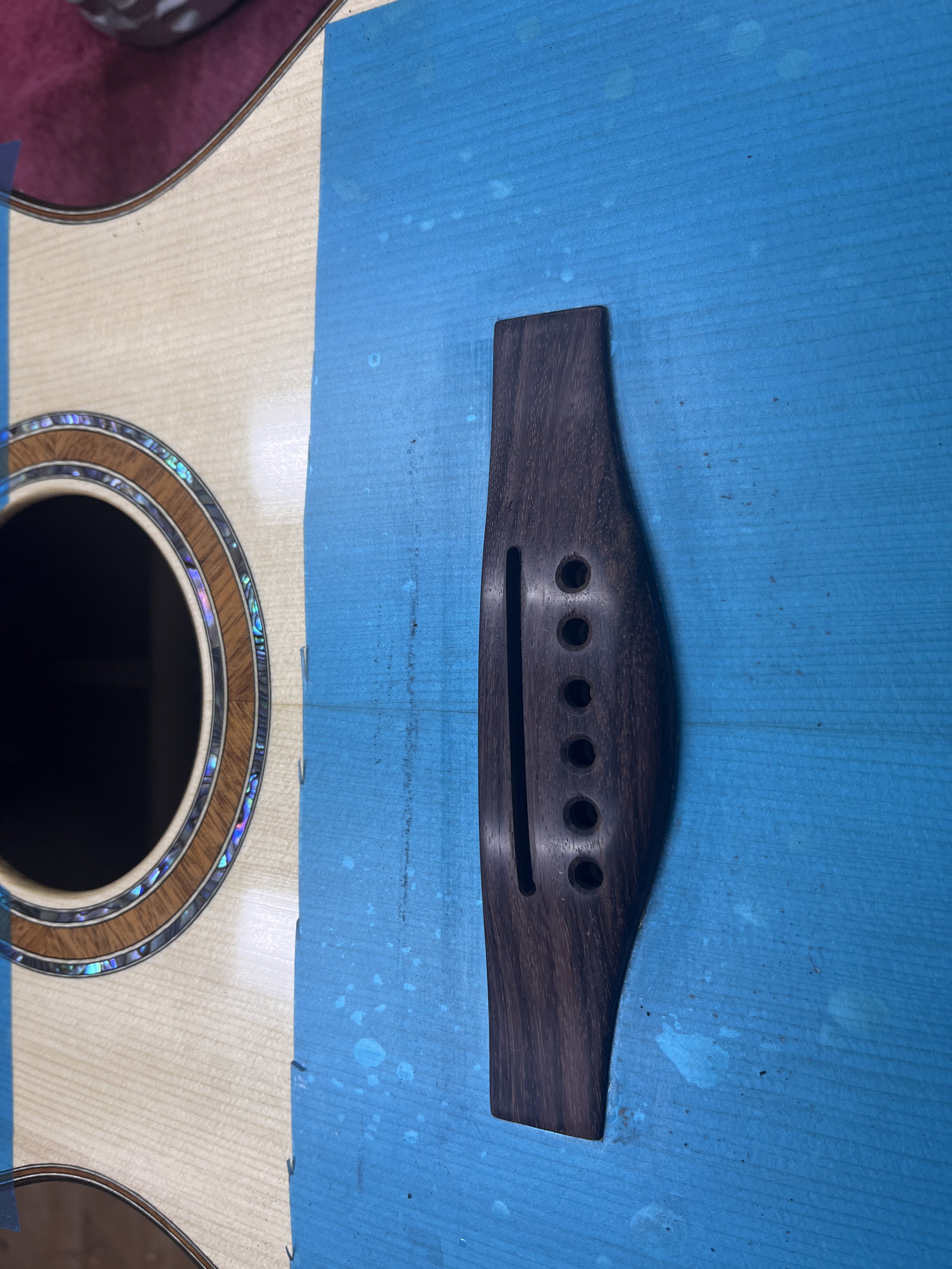

I scrape away the finish before gluing the bridge. A properly sharpened chisel with a burr makes this easy. Those of you with a good eye will notice that the abalone rings are composed of larger pieces, not zip-flex. I don’t like seeing al the little breaks in zip flex. The rings are not single pieces, but it is very hard to see the joints.

Bridge glued and saddle slot routed. I prefer to rout the slot after gluing the bridge. With a good jig, compensation of the saddle is easy.

Completed front view

Completed shoulder view

Closeup of inlay

December 7, 2025:

The “Ganesha” guitar has finish on it and is almost done:

I also has a new build going for a Lyme, NH customer. This one will be a super-jumbo with a 17" lower bout. I am not cloning the Gibson J-200, since I always add my own look to my work.

This will be a very local build, featuring tonewoods grown in my hometown of Lyme, NH. In previous posts I've talked about the red spruce I have from Lyme, and I will be using it on this build, as well as some cherry harvested by me from my property about 10 years ago. For a guitar this wide, I don't have local material large enough for 2 piece tops of back. Each of the plates is a 4-piece, bookmatched from 4 sequential cuts. While I have some very premium tonewoods in my stash, I enjoy building with local materials and I like to think that its the builder that makes a good guitar.

There are some inlays on the back that are symbolic to the client (and we are embracing the 4 piece back with the layout of the inlays):

The rosette is sapele with curly maple rings, and a diamond MOP inlay (which will feature on the fingerboard and headplate):

I have not posted about this before, but I use some free plate tuning techniques during my build/voicing process. it helps me select tops for different guitars and helps identify resonances and stiff spots in the top/bracing.

When I was evaluating tops for this guitar, few had the necessary cross grain stiffness for a body this wide. Looking at the free plate Chladni patterns, tops with good cross grain stiffness make well defined "ring" modes at the main top frequency. This is the top I chose for this guitar:

In addition to the well defined ring mode, this top had very clear tap tones which held their pitches -- no fluttering or warbling.

The following top was rejected for this guitar. You can see the "ring" is very narrow, indicating poor cross grain stiffness for a top this size (I will cut this top down for a smaller guitar):

November 22, 2025:

First, this guitar has been delivered to a happy customer:

Bookmatched black walnut on the headplate, to unify the theme of the guitar with the bookmatched back.

My “signature”, my initials inlaid in Morse Code. This time on the front of the bridge.

Nice bookmatched black walnut, local to Lyme NH.

Second, I have a lot of progress on the small jumbo. This guitar also gets laminated side for rigidity and projection (it will be used for performance):

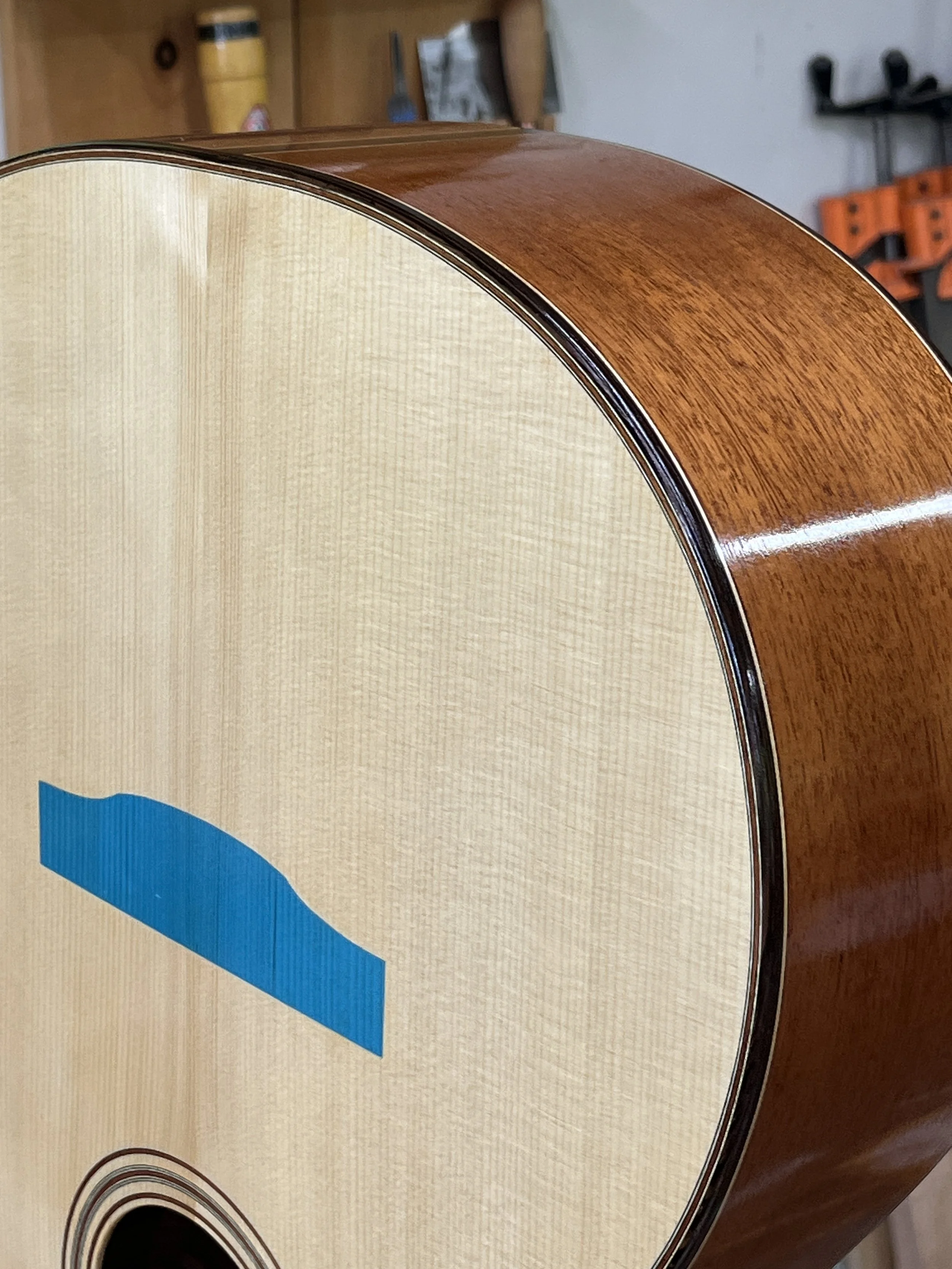

Box closed and bound:

This little Stanley block plane (upgraded to a Hock iron), does a great job cleaning up the bindings. If it is sharp…

Getting the head plate ready for binding. There are so many little steps in this process! This guitar gets a custom cut MOP Ganesha, the Hindu god of good luck and patron of arts and sciences (among other things).

Mock-up, almost ready for finishing:

Layout for a custom pickguard from Holter Pickguards:

October 30, 2025:

Happy Halloween! I’m dressing up as a Luthier today!

In addition to the two 00 guitars I have mentioned in previous posts (and updates described below), I have another guitar started. This one in a 16” small jumbo, with red spruce top and black cherry B&S. I couldn’t start this guitar because I was waiting for a few pieces of custom MOP. Now that has arrived and this guitar gets moved to the top of the queue because it had a deadline (late December).

I have the plates braced and mostly voiced. The soundboard is super lively and excitable. I do the final voicing of the soundboard after it is glued to the rim. Then I tune the back to be a semi-tone or tone higher in pitch.

I have closed the box on the mahogany 00. This guitar is incredibly resonant. The whole box just quivers and pulsates when I tap the bridge area.

And I am getting ready to do the final setup on the Walnut 00. It turns out that black finishes are much harder than natural wood. The grain of the wood hides many of the finish imperfections…black pigment highlights them all. This turned out great, and I think its a real head turner. I will string it soon.

October 22, 2025:

I am finishing up the walnut guitar described below, and hav started a new one. This one is 00 size, 25.5” scale, 13 fret neck, local Lyme NH spruce and Cuban mahogany. This guitar will follow a traditional build withe single ply sides and cloth reinforcement strips. W are aiming for a more vintage, open sound.

The mahogany was salvaged from hurricane damaged trees in Florida — Cuban mahogany refers to the species (swietania mahagoni) — and it also grows in Florida. This set of wood has amazing ribbon figure with a fair bit of ripple or curl sprinkled around. The sides actually have better figure, so stay tuned!

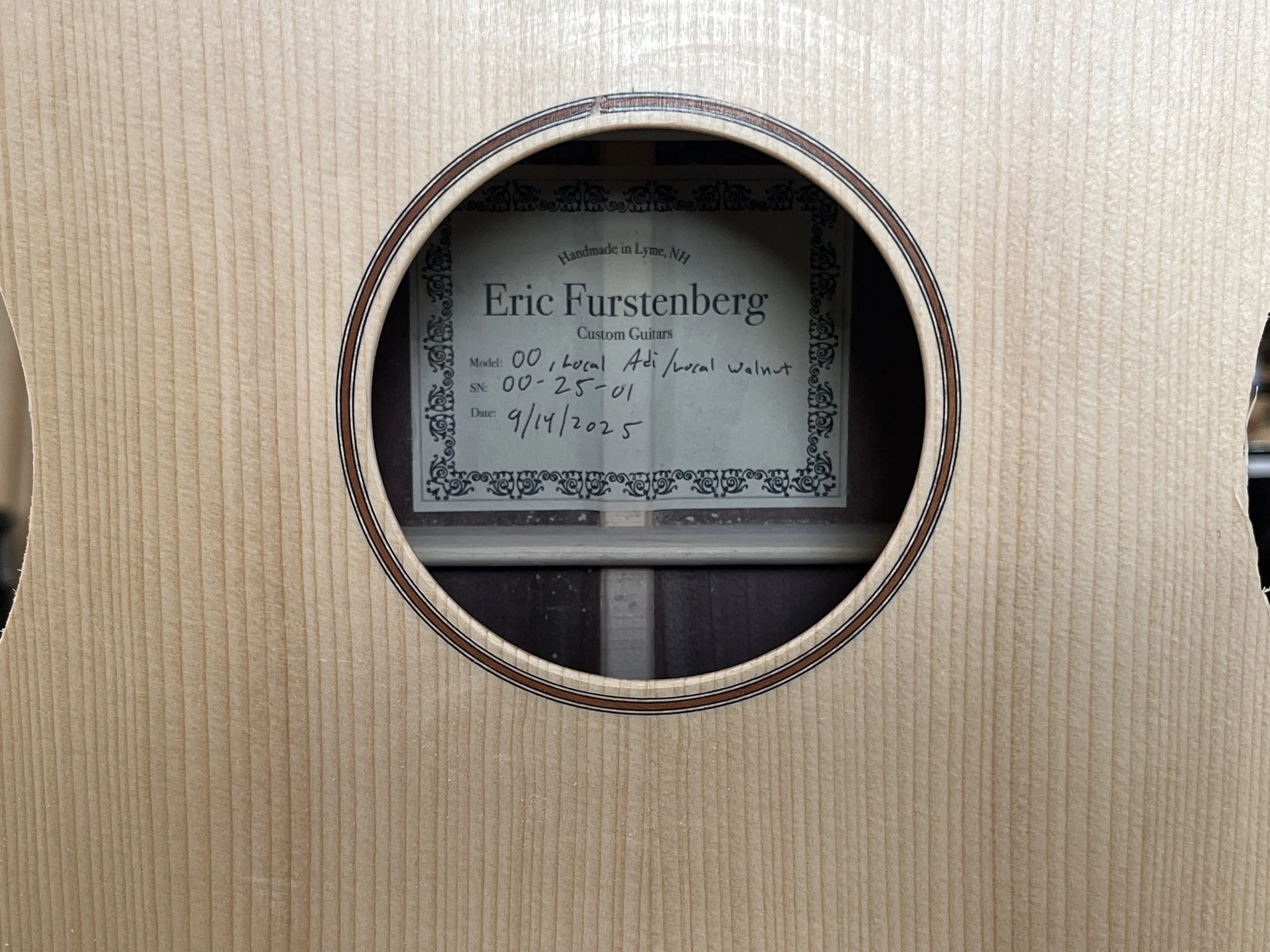

September 15, 2025:

00 size, 25.5” scale, 13 fret neck, local Lyme NH spruce and black walnut. This guitar has laminated structural sides for increased clarity, volume and projection.

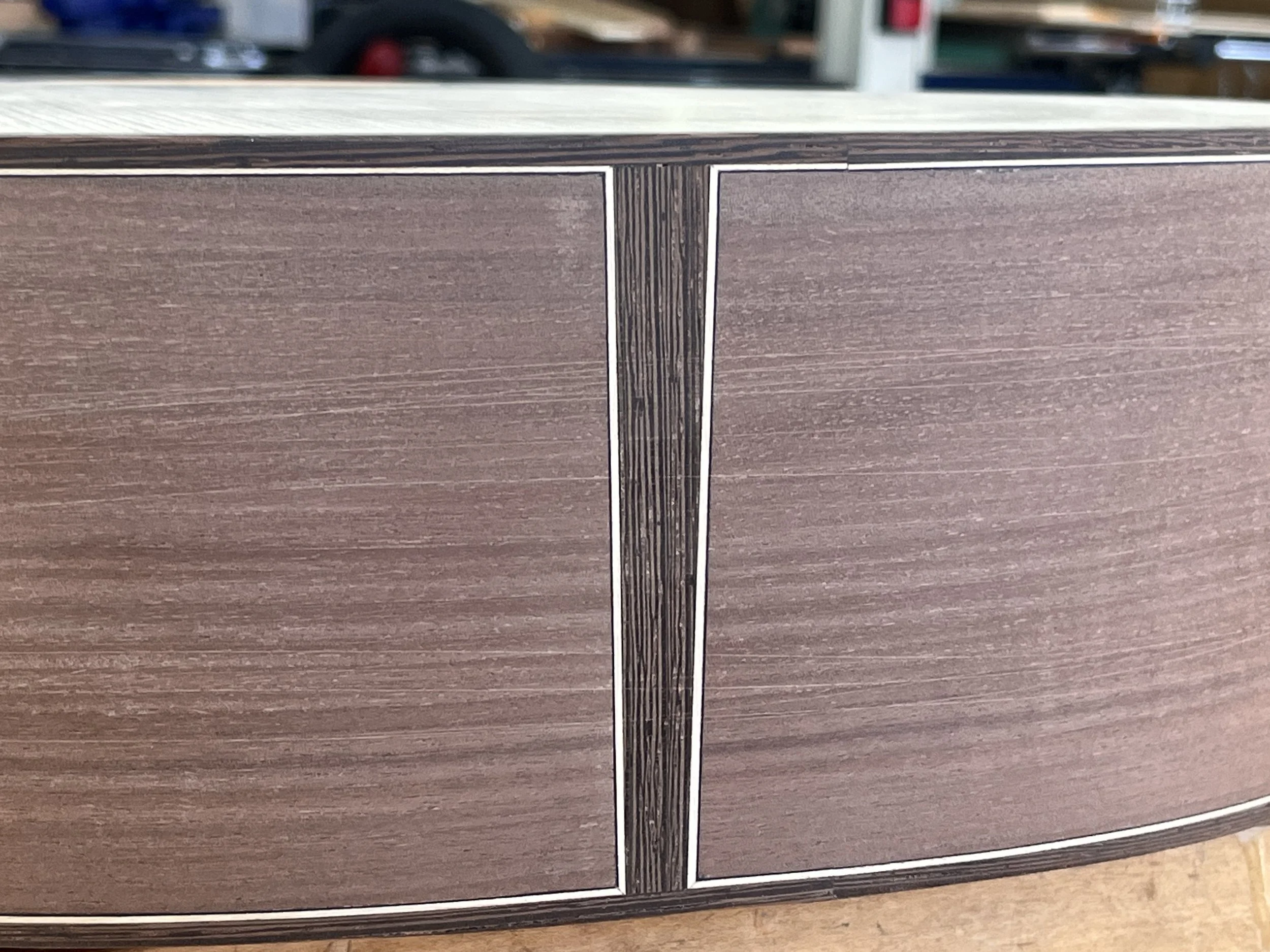

This guitar is a good example of using bookmatched wood grain for visual effect. The back features the light colored walnut sapwood in a striking point pattern:

I like to repeat certain elements of the design to create a theme and unify the piece. The headplate is also bookmatched walnut, with a touch of sapwood at the bottom.

Finally, the two piece laminated neck is also bookmatched, and the grain orientation follows the contour of the Martin style volute on the back of the headstock:

The soundboard is colored black, with the purflings and rosette revealed:

Additional images:

Recently completed:

Custom 3/4 size Dread:

15” lower bout, 22” scale, sitka spruce top with black locust back and sides. This guitar is for a serious player with shoulder mobility issues. We have therefore decided on a 22” scale with a 12 fret neck joint. It is very comfortable to play. Gold Gotoh tuners with spalted maple headplate and rosette inlay set this guitar apart visually!

Sound samples of the 3/4 Dread, by Derek Burkins of Thetford, VT:

OM:

Red spruce and Mahogany:

Lightweight Dread:

Dreadnought guitar built for light strings and fingerpicking. Red spruce and Mahogany, with figured maple bindings. Headplate “fan” inlay inspired by Federal style furniture and architecture. Makers mark (my initials) inlaid in morse code on the back of the headstock.

Sound samples of this guitar: